View cart “Mushroom” has been added to your cart.

€3.00

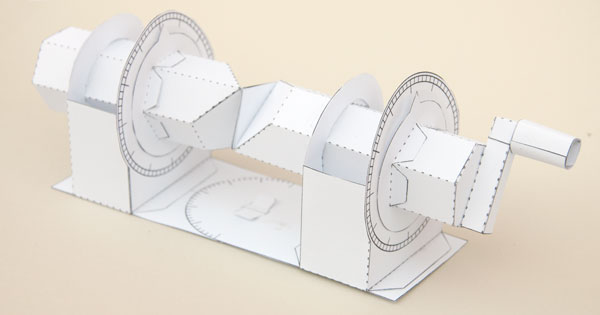

Paper Universal Joint

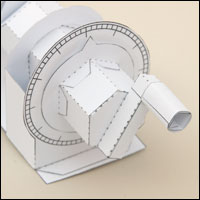

The universal joint is a mechanism used to add a joint into a drive shaft, with the universal joint in place the drive shaft can be flexible.

Here is a quick to make model so you can see how the universal joint works. As a member you can download the parts at the end of this post, non members can download the model for a small fee.

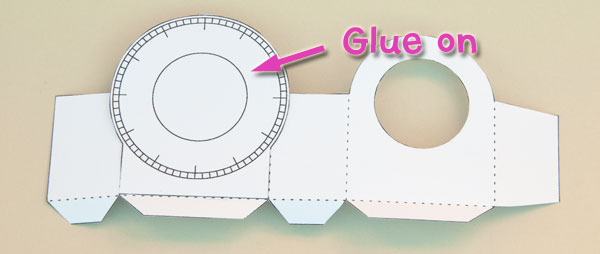

Print out the three parts sheets onto thin card. Score all the and cut out the holes before cutting out the parts. Both these jobs are easier on whole sheets of card. Only cut out one hole in the support piece.

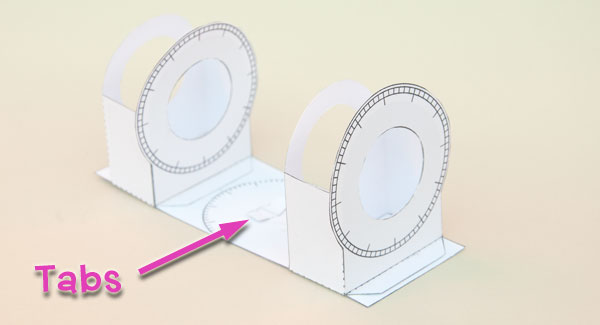

Glue the two dials into place on the fronts of the support pieces.

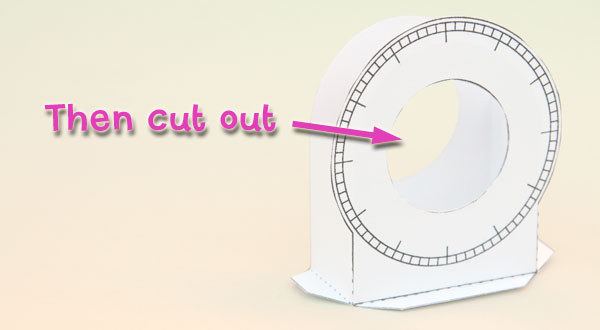

Once the glue is dry, cut out the hole fold round and glue the support together.

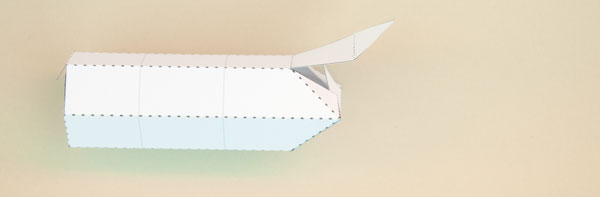

Glue together the two drive shafts…

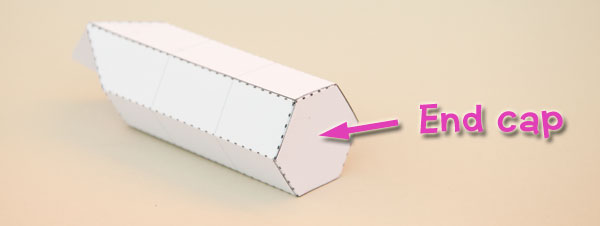

…and glue on the end caps.

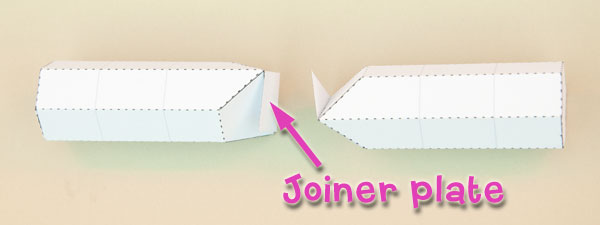

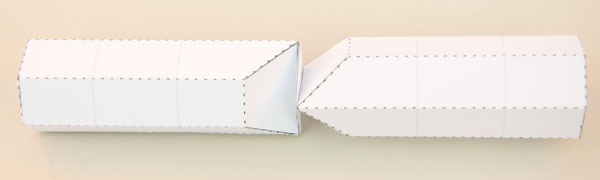

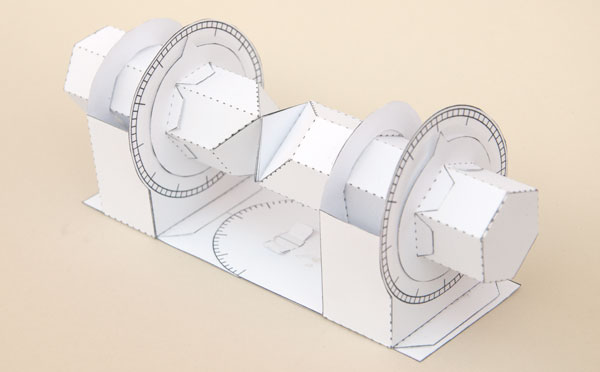

Glue the joiner plate onto one of the drive shafts

Add the other drive shaft to the other side with the tab at ninety degrees.

Thread the tabs from one base plate through the hole on the other base plate, don’t glue it though, it needs to be free to move.

Using the grey areas for alignment glue the two supports onto the base.

Thread the drive shafts into the supports with the washers in place on the outside of the support. Note that the washers with the arrows are used on the dial side of the supports.

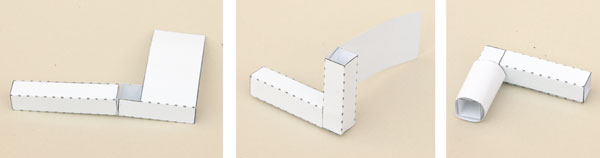

Assemble the handle in three stages as shown above.

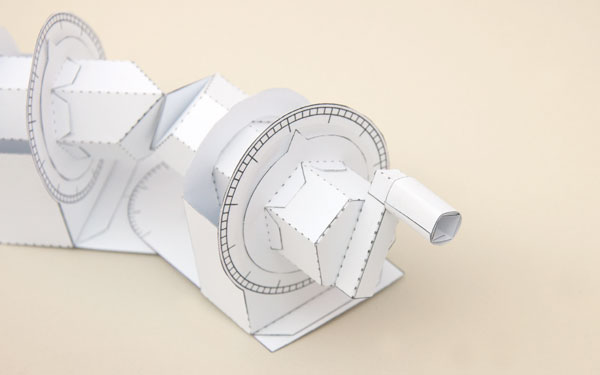

Glue the handle to the end of drive shaft.

Once the glue is dry the model is complete!

Turn the handle and the driveshaft turns along its full length. Experiment by bending the base, see how the shaft still turns with a bend in it. There is a short-coming with the universal joint though.

Try this. Rotate the shaft at a constant speed at one end. While the shaft is straight the other end rotates at the same speed but add a bend and the shaft after the bend speeds up and slows down. Use the pointers and dials and you can see how angles change in a complete rotation. You’ll notice that the greater the angle, the more noticeable the effect.

Car drive shafts use constant velocity joints rather than universal joints to overcome this problem. That’ll have to wait until another model.