In the previous Rotating Reciprocating Vertical Shaft (RRVS) Mechanism the range of movement is limited to around ninety degrees in either direction. It worked well for the Disagreeing Dog and I’m sure it will be suitable for a whole range of other models where a simple side to side movement is needed.

In the world of mechanisms there are always other ways to create the same type of movement. I’ve been experimenting with a new design that would allow a wider range of back and forth movement. (Up to three sixty degrees and beyond, in both directions) The other property of this mechanism is that the drive is much more accurate. Back and forth movement will be within a predictable, repeatable range. Here the plan:

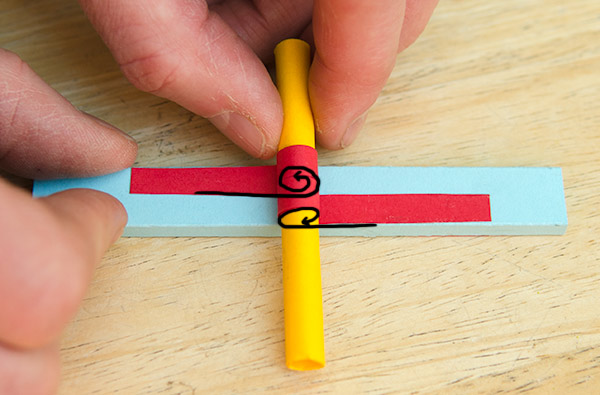

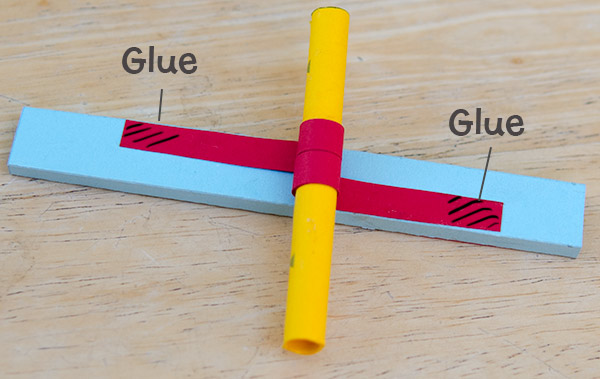

The yellow shaft is the driven shaft. This will be attached to the character in the model. The ends of the two red strips are glued to the yellow shaft then both are wrapped a couple of times round the shaft, one of them clockwise and the other anti-clockwise.

The ends of the red strips are then glued down to the blue drive bar at opposite ends of the bar. With the shaft fixed but free to rotate, moving the drive bar back and forth rotates the shaft back and forth.

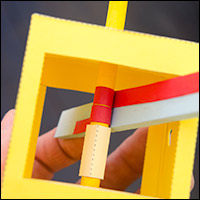

Having fitted the shaft into a box and established that the drive works, my next step will be to create some sort of linkage that can drive the blue bar back and forth.

Having fitted the shaft into a box and established that the drive works, my next step will be to create some sort of linkage that can drive the blue bar back and forth.

The whole mechanism works similarly to a rack and pinion drive but is far better suited to paper as both teeth and gears are hard to make accurately.

I’m calling this the RRVS Type 2. Short for Rotating Reciprocating Vertical Shaft. Looking good so far!