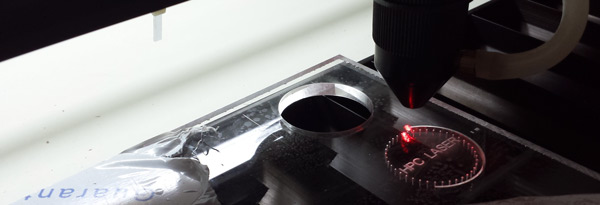

I’ve spent a fun afternoon visiting HPCLaser and learning how to use this laser cutter 🙂 The Laserscript cutter uses a water cooled CO2 laser and a series of computer controlled mirrors to cut and engrave a variety of materials. Expect YouTube videos as I get everything set up. Meanwhile, take it from me and the small army of people who helped me unload the laser from the car, if you buy one, rent a van or have it delivered!

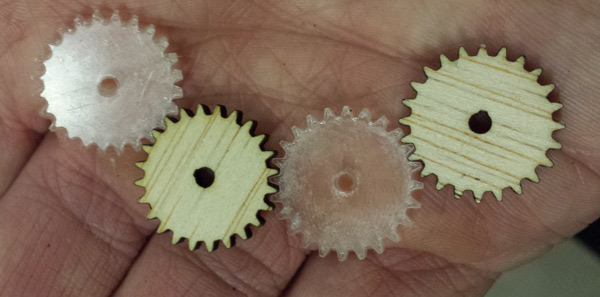

The laser will happily cut out even tiny parts with incredible accuracy.

Cutting perspex is easy and the polished edge of the finished product is a fine sight!

It turns out that these filigree gears break easily if you sit on them. 🙁