The maximum sheet size I can fit in the laser cutter is 300 x 500mm. With sheets smaller than this there can be tendency for them to warp a little lifting slightly at the edges away from the cutting base. Up until now I have taped down the plywood with masking tape but this can be awkward as the base board in the laser cutter is slatted.

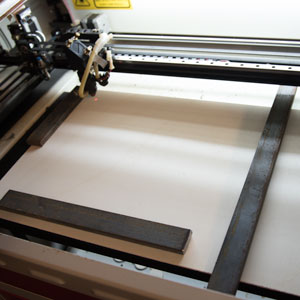

I’ve tried holding wood down with a variety of spanners and hammers with some success so I thought I’d expand on this technique with some bespoke materials. I paid a visit to our steel supplier and for a couple of pounds sterling he cut me a selection of lengths of 4mm thick steel bar.

Perfect. Just thin enough to fit under the laser head but heavy enough to hold down any warping wood.

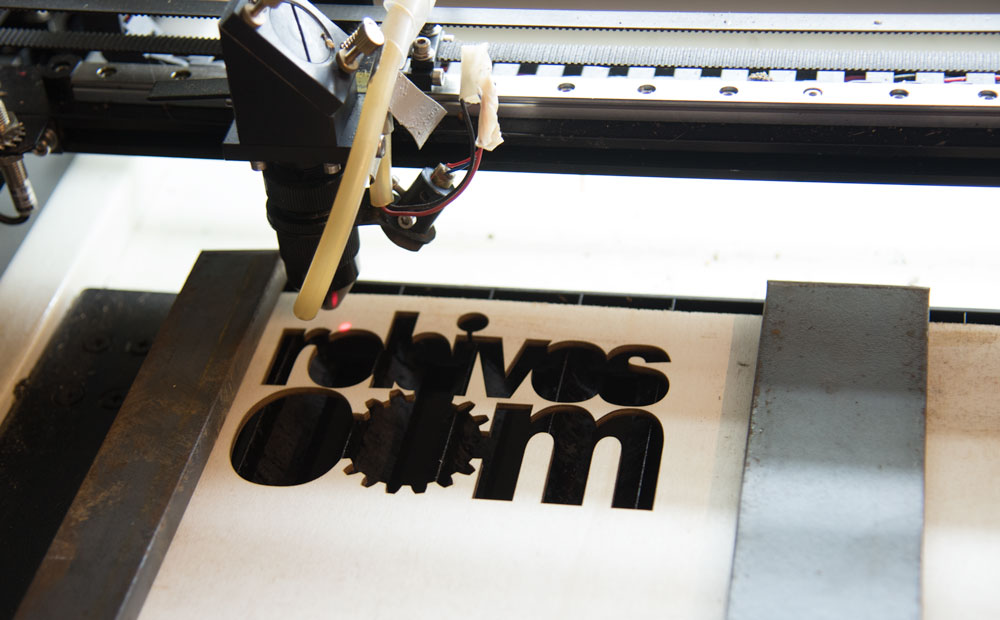

Ta daa! They work a treat and no tedious un-picking tape once the cutting job is complete.