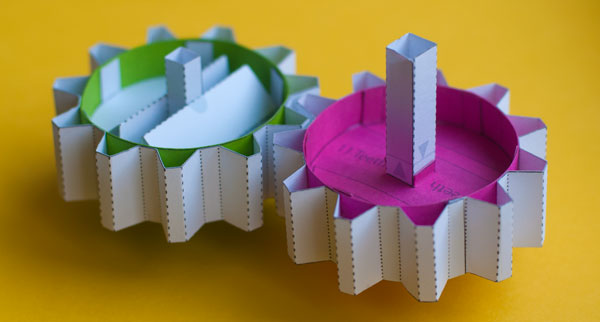

I’m in the process of putting together another Zine, this time on the subject of gears. I thought it would be fun to use photographs of paper gears as illustrations. It has turned out to be instructive as well 🙂

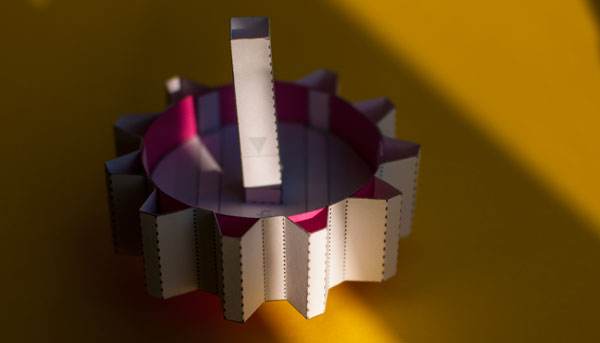

This eleven tooth prototype has problems with the axle moving from side to side. As well as addressing this problem I would also like to try out using a circular axle rather than the square section ones I have used up until now. Square section tubes have the advantage of being easy to assemble accurately and easy to fit into place. They have the disadvantage that a square peg in a round hole doesn’t make for a good fit.

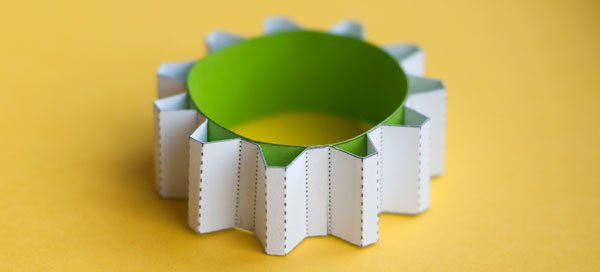

Starting with a ring and eleven teeth…

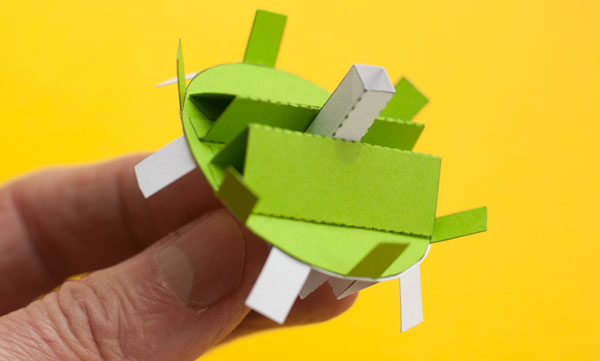

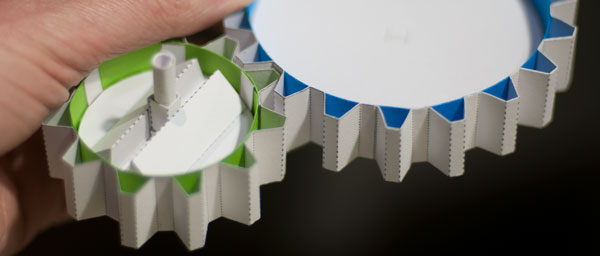

I added triangular section pieces, to each face adjacent to the square hole. The two faces have the stiffeners running at 90ª to each other. One piece takes care of front to back movement, the other takes care of side to side. I’ve also made the hole slightly smaller with the square section tube now only 6mm on a side.

Here, the centre piece is fitted into place.

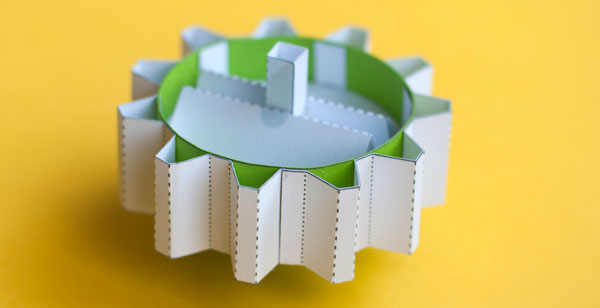

Old vs new.

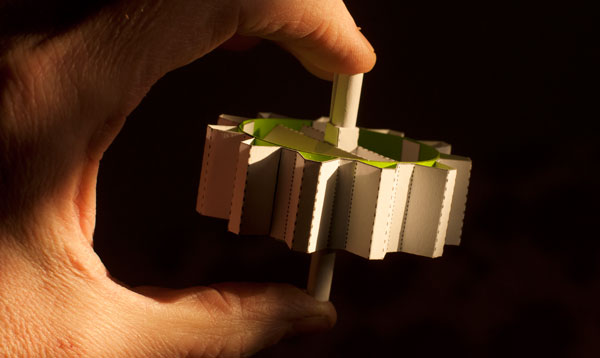

And to complete the gear, I’ve threaded a tight fitting rolled tube through the square tube.

Here, fitted through a 6mm diameter hole, the gear runs smoothly with very little play.

Next to mesh it up with this 21 tooth gear, then on to photography.