I’ve been working on poseable dinosaurs and poseable maquettes recently. Both share some common design feature but need different sized parts. Because many of the limb parts are tapered the design process for each segment has been time-consuming. It was with this in mind that I thought would have a look at parametric design. In parametric design, you can link dimensions together so that if one measurement is changed, the linked measurements are automatically recalculated. This can be a real time saver!

I’m using Autodesk Fusion 360 which is available for download here. I’m new to this so the design I have come up with has several shortcomings. Thanks to the people on the Fusion Forum for your help and advice!

If you have some knowledge of Fusion 360 you can download the file here to try out yourself. Let me know if you make any improvements!

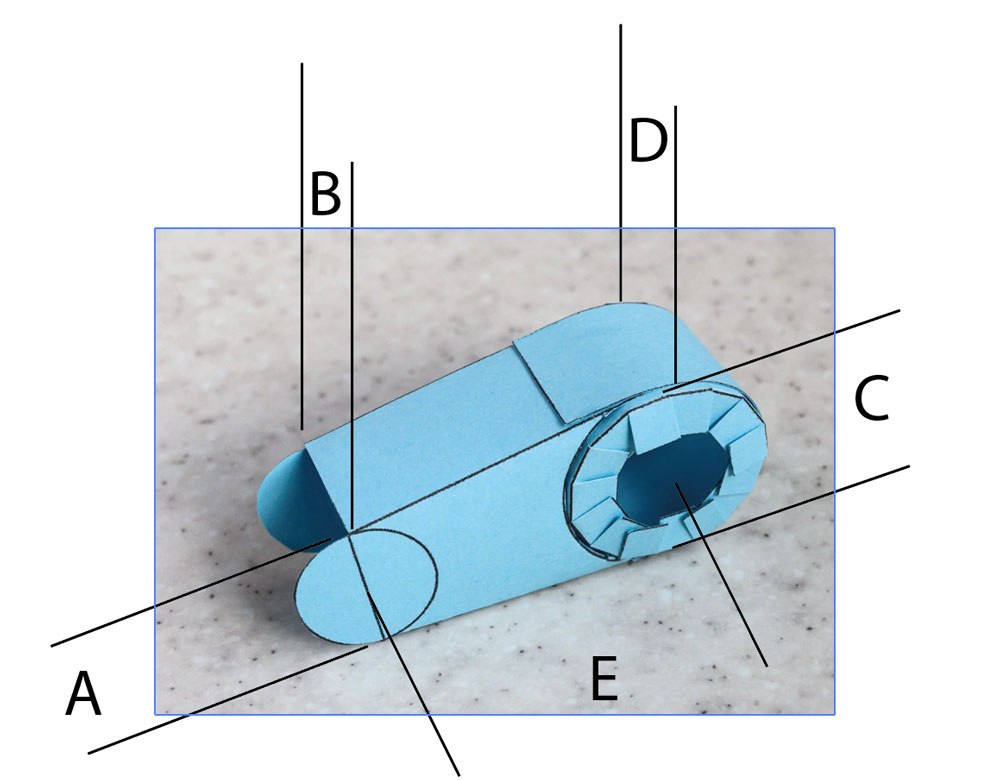

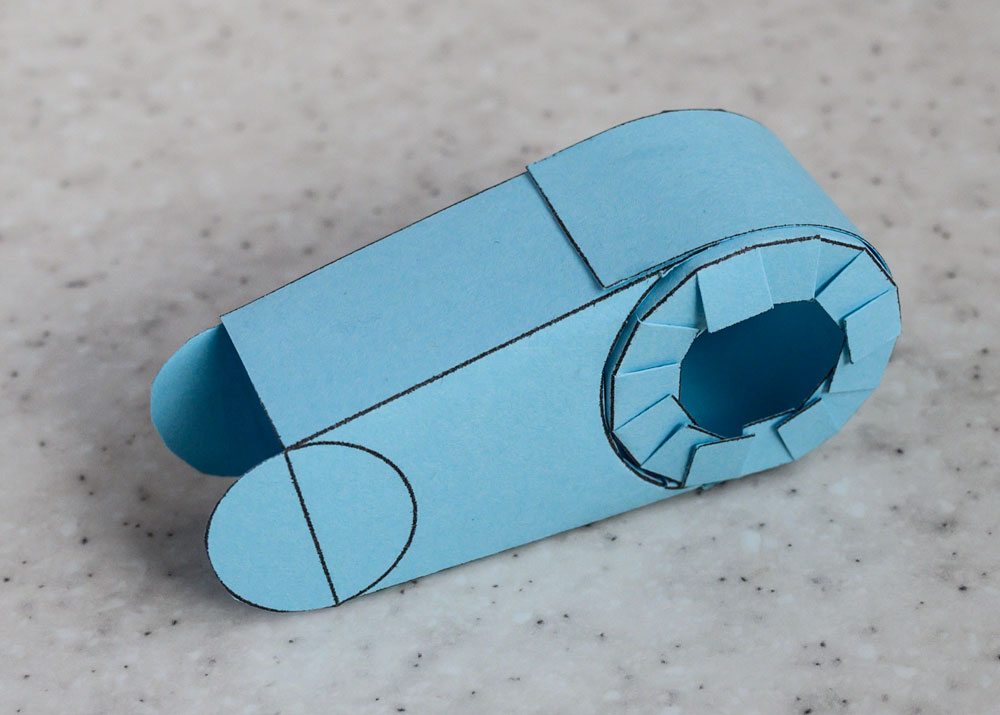

The file is designed to aid in making parts like this…

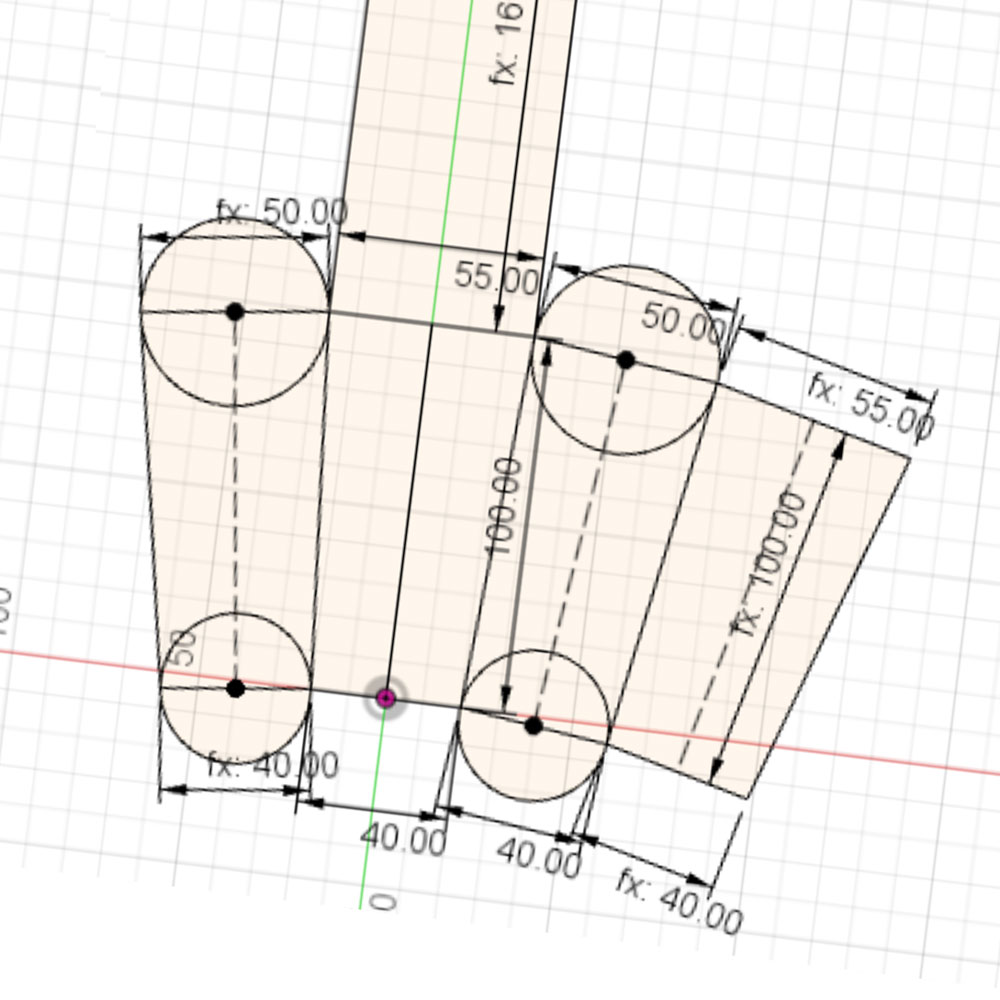

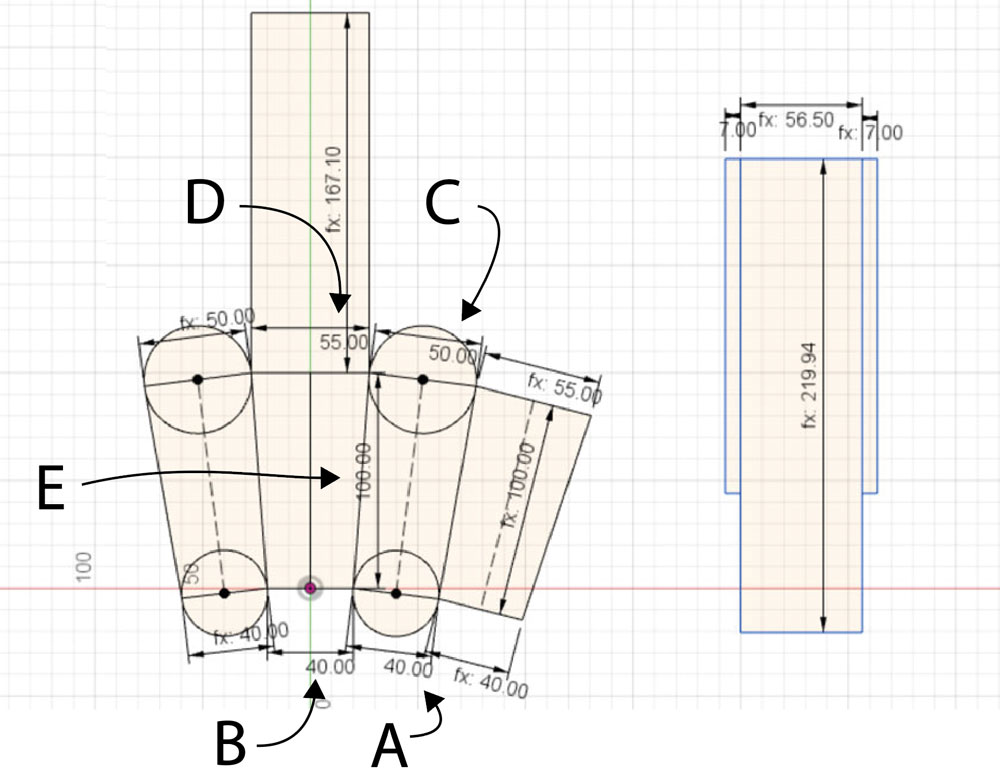

The dimensions were set in the sketch and the net of the part was automatically calculated.

View this post on InstagramA post shared by Rob Ives (@robivescom) on

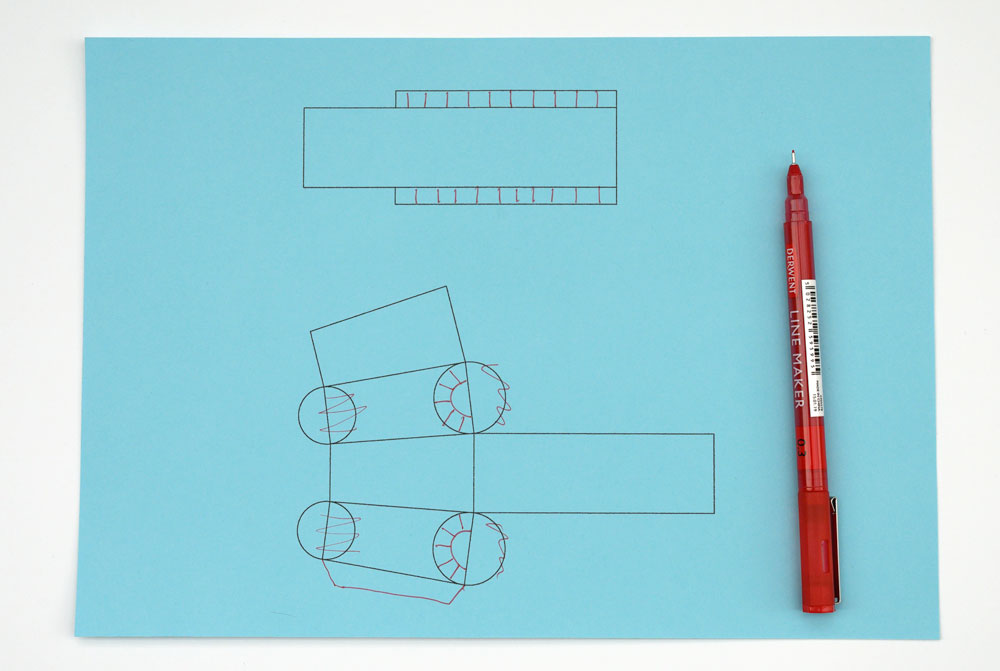

The completed parts were exported as a dxf which I then imported into Adobe Illustrator to be printed out.

The file from fusion needed a little work. In this case, I added the various tabs with a pen. In future versions, I’ll edit the parts properly in Illustrator.

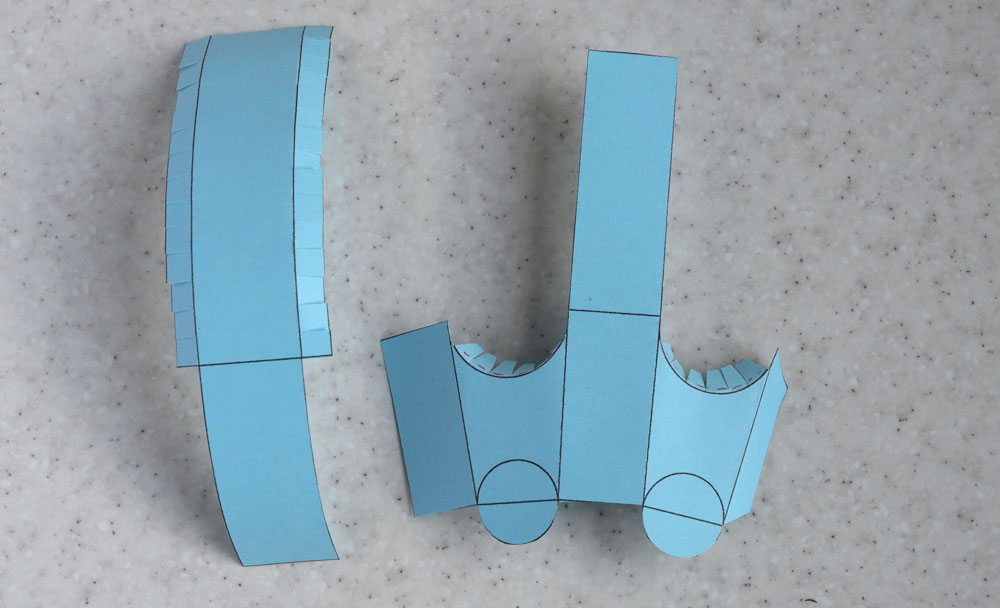

Parts printed onto card and cut out ready for assembly.

The cylindrical core is free to rotate. Make a few, change them together!

https://www.instagram.com/p/B2WlIaDnLH2/