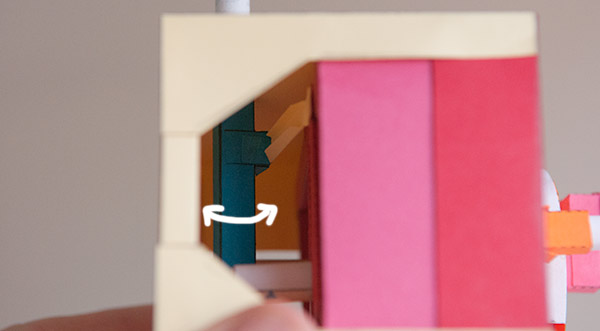

The eagle mechanism is a made up of three basic mechanisms. A Geneva drive which divides the rotation by four, a crank and scotch yoke to convert the rotary motion from the drive to a back and forth motion and finally, a mechanism to convert the back and forth motion of the scotch yoke to the rotary motion of the vertical shaft. My first draft had a peg sticking out the side of the vertical shaft and a simple link joining them together. It worked but the extreme ends of the yokes travel the motion of the vertical shaft slowed right down.

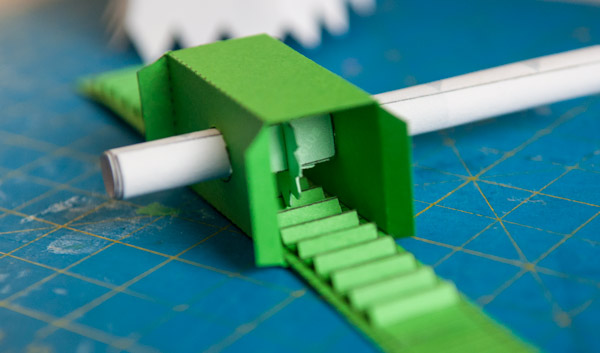

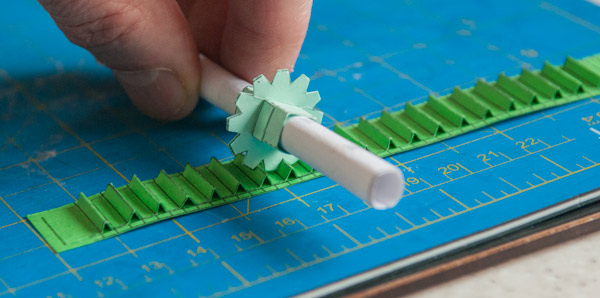

I wanted to make the rotary motion more consistent so that it didn’t slow down at the ends of the range of travel. To that end, I’ve put together this flexible rack and pinion drive

By fitting the drive parts inside this box section the rack is held against the pinion wheel. Pull the rack back and forth and the pinion turns. Next step, fitting the various mechanisms together into a whole unit.