More experiments with paper gears. Most modern gears use an involute profile. (more of this in a later post) The result is that gear teeth on smaller gears, ones with fewer teeth, have markedly curved profiles whilst the ones on larger gears with more teeth are closer to straight lines.

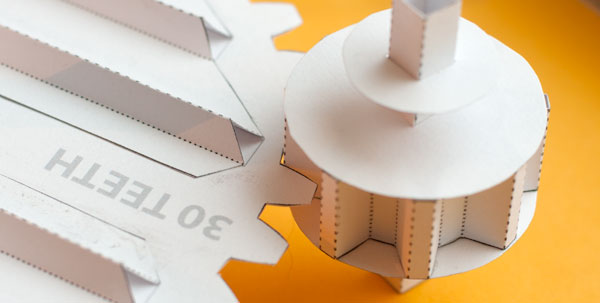

I was looking at the Big Gear project that I produced the other day and noticed a couple of problems with it. Firstly, the big gear has thirty teeth, not forty (!!) Secondly, in my model it worked beautifully in one direction but was sticking running and backwards. Looking at the way the teeth were sticking I wondered if it was because the gear teeth are straight sided.

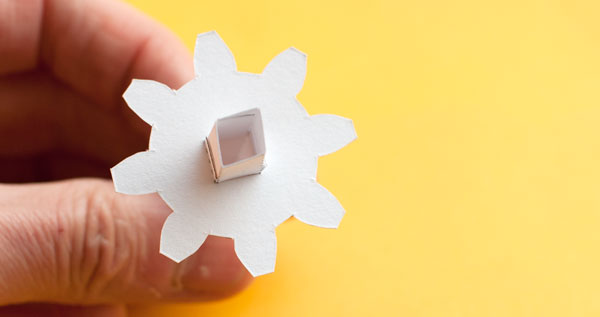

This close-up shows the original gears. Notice that I can add the small curve to the teeth on the large gear as they are a cut-out shape but not on the small gear as the teeth are made from card folds. Perhaps if I reverse them…?

Obviously I can't make both gears flat otherwise they'll just come apart too easily. By making the eight tooth gear the flat, cut-out gear, I can shape the teeth to be much more curved.

The downside is (and there's always a downside) that the big gear, with its folded teeth, takes longer to construct. That said, it wasn't too bad. Just need to fit the whole thing into a box for testing.