Win this Planetary Gear here!

Also on instructables.com

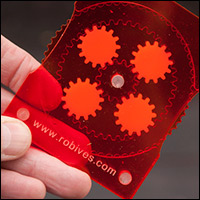

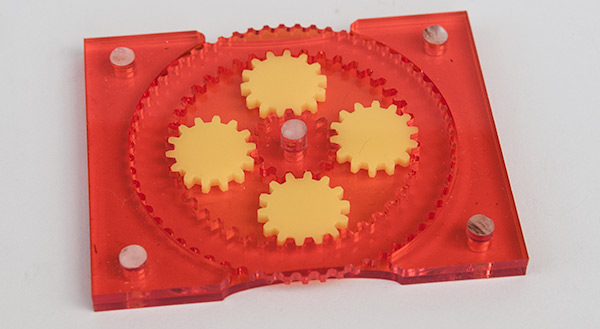

This tactile and delightful looking mechanism is a planetary gear. So named for the four planet gears orbiting the central sun gear. I’ve put this project together as part of my learning-to-use-a-laser-cutter experiments.

If you would like to give it a try all the instructions and files are below. There is also a chance to win one of these mechanical marvels at the end of this post.

Instagram Link Embed by embedinstagram.com

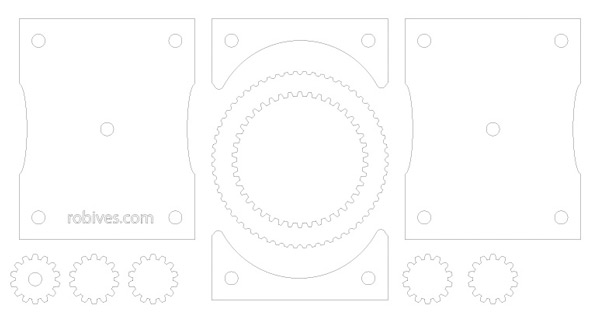

The parts are all laid out in a pdf file and then transfered to the Laser Cutter software. I’ve made the file available to download for free here. I’ve left it as a pdf file as, if you have, or have access to, a laser cutter then you will know how best to convert it for your machine.

Even if you don’t have your own laser cutter you may well be able to find one that you can use in your local area, perhaps in a FabLab or a Hacker Space. These type of resources are popping up all over the place so it is well worth checking to see if there is one in your area.

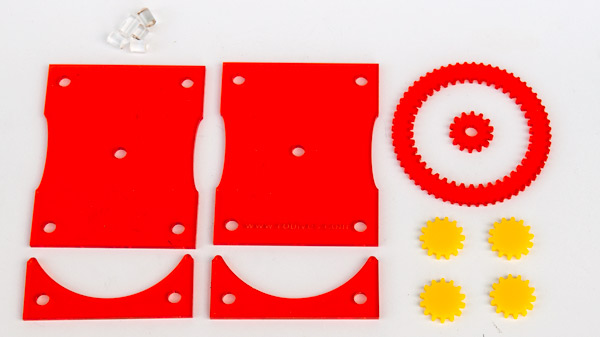

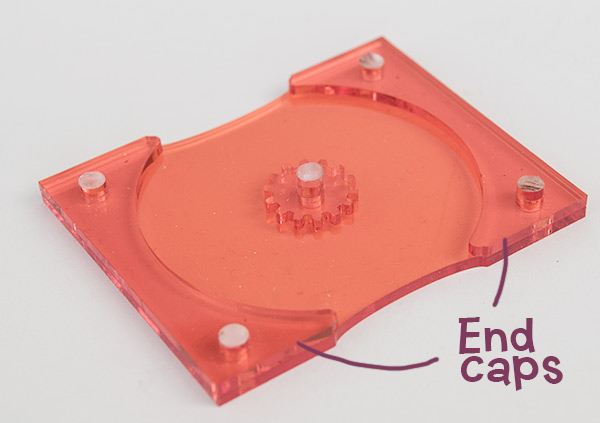

I’ve cut the parts out from 3mm acrylic sheet. (Perspex) I also used a length of 6mm diameter acrylic rod to hold everything together. There is no glue in this model. All the circular holes in the model should be a tight fit. It might be worth shrinking down the size of the circular holes to 5.6mm. Try cutting one circular hole and making sure that it is a tight fit with the perspex rod before you cut out all your parts.

Cut five 9mm long lengths from the 6mm rod. I’ve used a junior hacksaw. There must be a better way! Let me know if you know of a proper tool for the job.

Here are all the parts laid out ready for assembly. I used a different colour of perspex for the planet gears so that they stand out in the finished model.

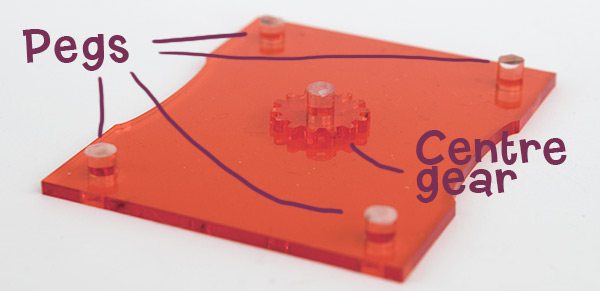

Fit the five pegs into the five holes of the back plate. A hammer can be handy at this point if the pegs are a really tight fit.

Tap the centre gear onto the centre peg. This gear is fixed, it should not be free to rotate.

Fit the two end caps into place and tap them down.

Drop the large ring gear (the annulus) into place between the two end stops. Space the four planetary gears around the central gear.

Finish off the gear by tapping the top plate into position. Turn the annulus gear and watch the planet gears rotating!

I have a planetary gear mechanism to give away to one lucky subscriber. Either leave a comment below or drop me an email. On 20th Jan I’ll put all the comments/emails into a hat and pick a winner. This competition is open to paid subscribers on robives.com, thank you for subscribing!