On the way back from Frankfurt we paid a return visit to the splendid windmill at Xanten. This time it was open to the public so we were able to have a good look around inside.

On the way back from Frankfurt we paid a return visit to the splendid windmill at Xanten. This time it was open to the public so we were able to have a good look around inside.

I had taken this short video of the windmill on Monday while it was operating. The sails were fixed today, I'm guessing as a safety thing. There were a lot of school children milling around, with the mechanism running it would not be long before one of them was milled, literally!

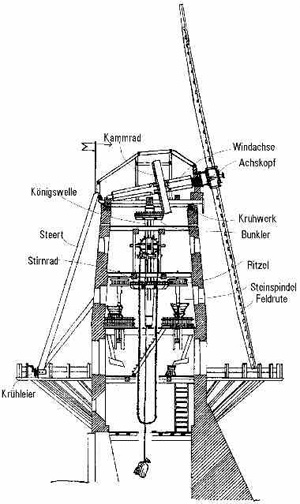

Michael42er pointed out this plan of the windmill in the comments of the original windmill puzzle post. Here you can see the entire mechanism in cross section.

Michael42er pointed out this plan of the windmill in the comments of the original windmill puzzle post. Here you can see the entire mechanism in cross section.

Notice how the blades are tilted backwards slightly with the main axle at a downward slope. This ensures that the vanes are clear of the body of the windmill, that way they don't crash into the body of the building as the vanes flex in strong wind. It would have been equally possible to build the windmill with a longer main axle but the extra leverage on the parts would put a greater strain on the axle bearings.

The windmill need to face into the wind to capture the most possible energy. Some windmills have elegant automatic mechanisms that keep the head of the windmill pointing the right direction. The windmill at Xanten uses the miller to point the vanes the correct way.

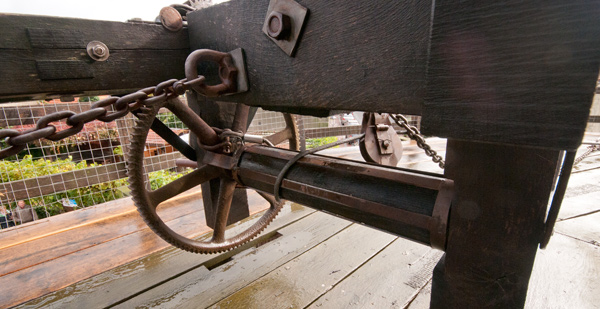

The large beams in the middle of the picture connect to the rotating top of the windmill. The gear head at the end of the beams doesn't actually touch the wooden planking. There is a geared wheel and a length of chain and steel cable. Turn the wheel to pull against the steel cable and pull the head round.

The closer look at the mechanism shows the steel cable wrapped around the steel drum.

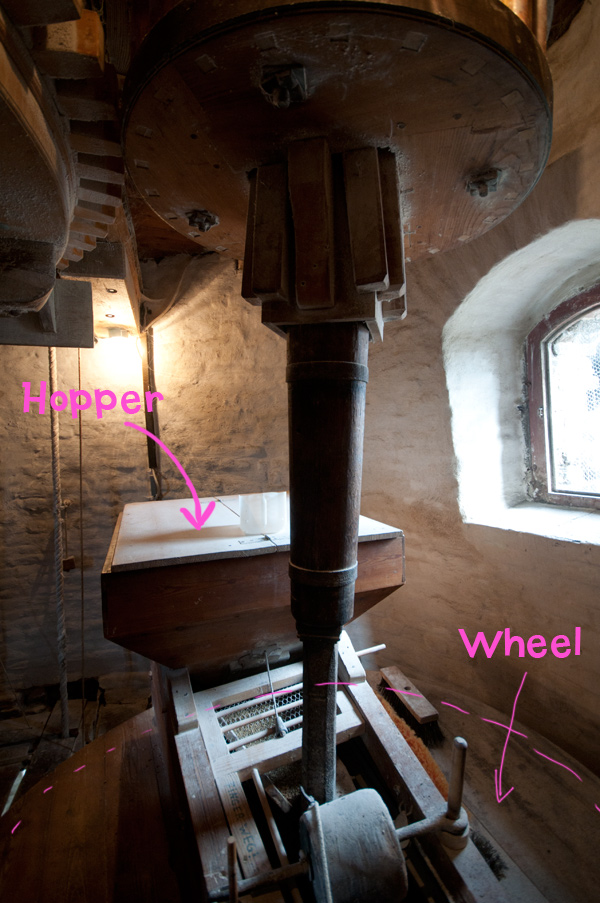

Starting from the top of the windmill. The vertical gear is on the main axle connected to the vanes. As the axle turns, it drives the vertical shaft which runs the full height of the mill. The teeth on the gears look new so I suspect that they might need changing fairly frequently.

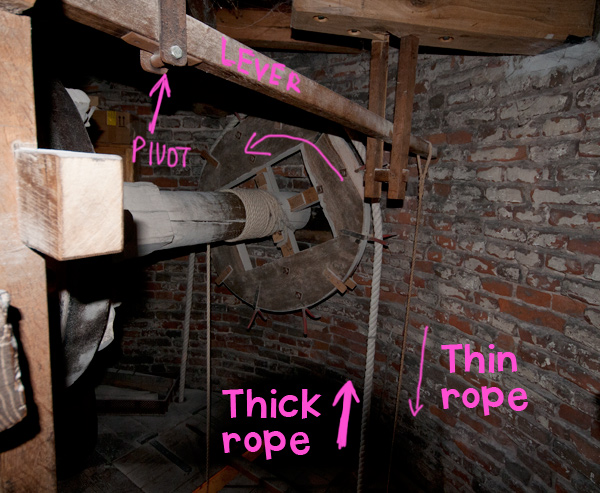

Half way down the mill we come to the mechanism mentioned in my Windmill Puzzle post. It consists of a large flat disk, held in place with wooden wedges and a vertical disk. This is, as most people have said, a device for hoisting sacks of grain into the mill. (Michael42er was first so I'll be dispatching a modest prize to him shortly. Thanks to everyone to emailed and commented, by the way, it was really nice to hear from everyone whilst I was on the road!)

The mechanism is a clever way to take power from the constantly rotating vertical shaft only when it is needed. When the vertical wheel is dropped down on to the flat wheel. It turns, driving the wheel at the back and lifting the sacks.

Notice the V shaped pegs on the lift wheel at the back. They provide a good grip onto the thick rope as it is lifting the sacks of grain.

A view from slightly further back. The thin rope is the control rope. As it is pulled down it pulls on the end of the lever which in turn lifts the drive wheel from the rotating plate. Pull the this rope to disengage the drive. There was a hook in the wall downstairs so that the drive could be easily disconnected and left unattended.

Another floor down and finally to the actually milling! Milling flour involves grinding the grain between two pieces of stone, one fixed and one rotating. The corn is fed through a hole in the centre of the top rotating stone. The wheel turns, grinding the grain. As it turns the grain and flour are pusged outwards toward the edges of the grind stones. Finally the flour escapes from the edges of the two stones and is fed into a hopper and thence into sacks.

There are two mill wheels in this wind mill, each can be connected or disconnected from the main drive. The big toothed wheel on the right is the main drive wheel connected to the main vertical shaft. The cage gear, on the left can be either engaged or disengaged with the main drive wheel by moving the end of the shaft from the floor above. (Next picture) There is another cage gear and grind stone of te right hand edge of this picture.

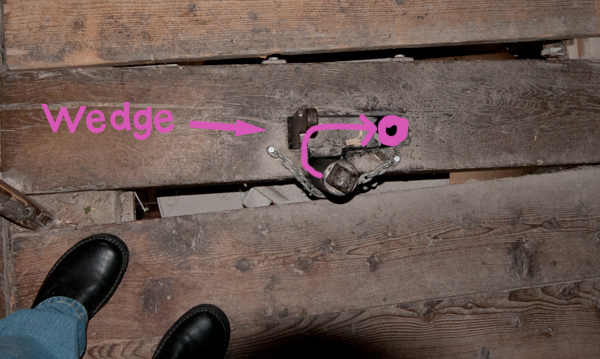

This picture is taken looking down at the top end of the cage gear shaft. The top of the shaft is the piece with the square end. To engage the drive, the metal wedge is lifted out then the wooden block to its right is removed. The end of the shaft is then moved left a little, up and fully right so that it sits where I have drawn the pink circle. Once in place the cage gear will be engaged with the teeth of the main wheel. The gear will be held into place by replacing the wooden block and the wedge. I'm guessing that the whole process needs to be done with the windmill vanes stationary.

Full sacks of grain ready for grinding.

Notice the doors in the floor. These are normally kept shut for safety reasons. As a sack is lifted up it flips the door up and open. Once the sack is clear for the door the door clatters shut once again.

I had a fascinating time looking round the windmill at Xanten. It was intriguing to see the elegant solutions to mechanical problems used by the engineers of the past. I'm sure many of the ideas will find a place in forthcoming paper models!