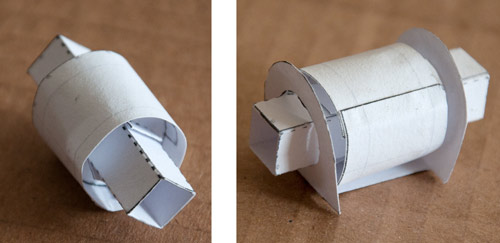

These are the rotor parts for the flappy arm model. The core piece is approx 14mm in diameter. I'm still not sure about running square axles in round holes. But I'm not sure about creating circular shafts out of cardboard either. So for the moment I'll stick with the squares.

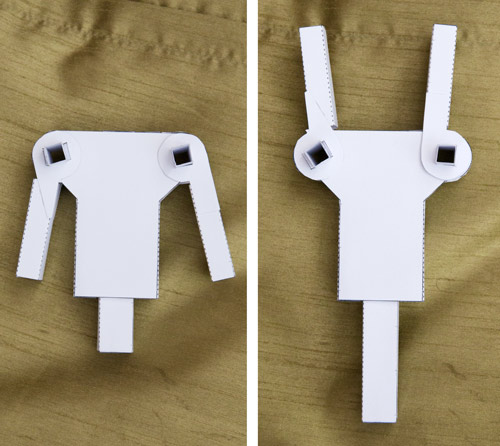

Here's how it all fits together. It works nicely and has a good range of movement. The mechanism is fun to make and interesting. I'm going to go straight for a completed model. I'll print out the photo above and sketch some ideas on top of it, lets see where we go!