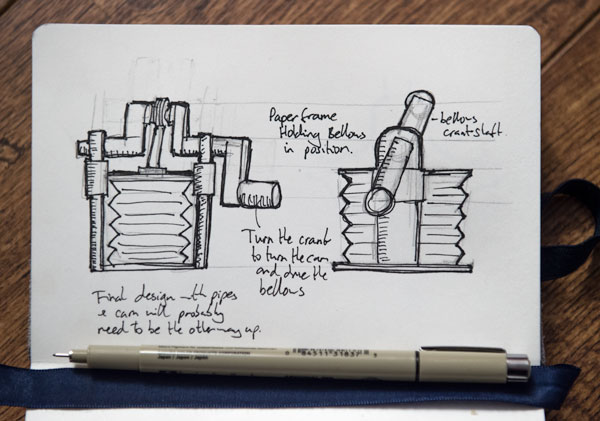

Next step in the bird box project. Bellows and crank. Turn the handle to pump the bellows. This is similar to the type three model I made before but the guide rails will keep the moving plate horizontal as it moves. There’s a problem though.

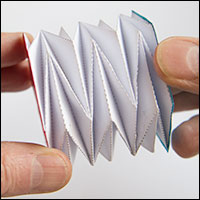

As the bellows move back and forth the plates twist in relationship with each other.

As the bellows move back and forth the plates twist in relationship with each other.

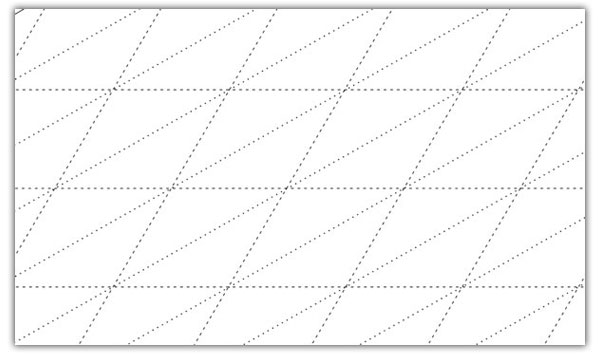

This is the net for a section of the current bellows design.

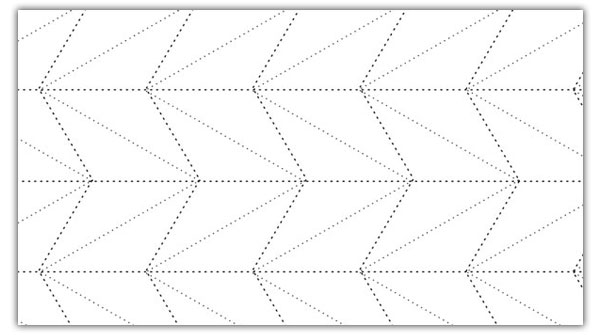

My thought was that if I flip every other row side to side, the rotation in the end plates should be canceled out.

Here’s the new layout.

It takes a little long to score the bellows but the end result works perfectly. No rotation at all!

It takes a little long to score the bellows but the end result works perfectly. No rotation at all!

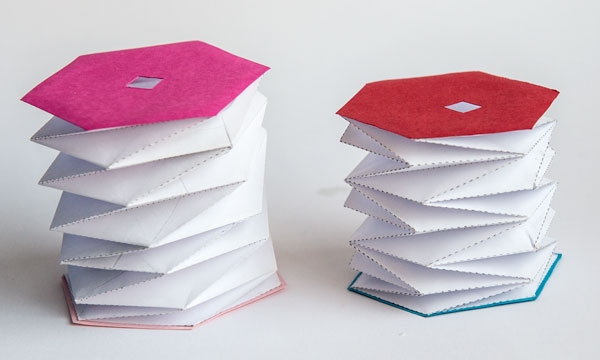

Here are the two test bellows side by side. Next step – connecting up the crank.