The heart of many automata, both traditional and the paper variety, is the cam. The cam is perhaps the most flexible way of driving a mechanism. By changing the shape of the cam profile all sorts of different movements can be described.

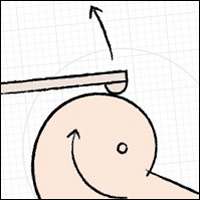

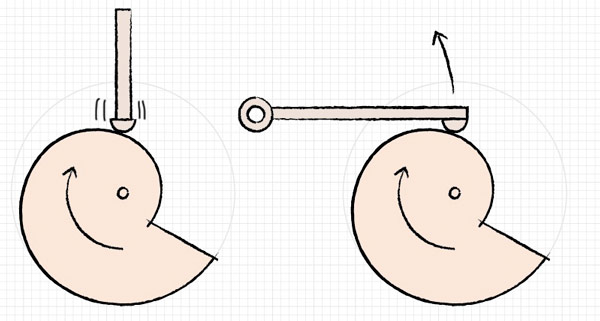

But on its own, a cam just goes round and round. To use the movement the mechanism needs a cam follower, the part that runs along the cam's surface. In more traditional automata, made from wood and brass, it is quite possible to run the cam follower so that it is perpendicular to the cam, as in the first picture above. In paper based models this doesn't work so well. By their nature paper models have more flex and tolerance. A perpendicular cam on a paper based model will tend to flex and bend rather than running smoothly up and down, not what you want! Paper is at its strongest when it is under tension (being pulled) To use this strength, cam followers in paper models tend to drag across the cam surface (above right)

No iFrame ‘;

print ‘

Using HTML 5 ‘;

}

else{

print’

‘;

print ‘

Using Flash’;

}

?>

The design of the part of the cam follower that touches the cam is important. There needs to be a finger shaped end to closely follow the surface of the cam. More complex curves need a narrower finger but, as is often the case with engineering and design, there needs to be a balance between fineness and strength. The animation above shows how well the narrow cam follower follows the cam compared to a stronger wide one.